Enhancing Performance Through Combined Systems

How combined systems become greater than the sum of their parts

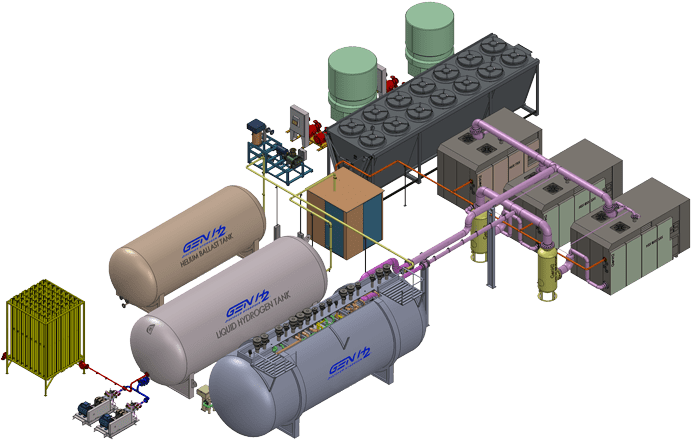

Hydrogen undergoes multiple processes to optimize liquefaction and distribution. GenH2 has created modular system components that can function separately or integrate into an all-in-one unit that accomplishes every step in the process. The integral approach of complete hydrogen systems will redefine the industry, as all the necessary processes to liquefy, store and transfer hydrogen are capable of being centralized or combined into a single all-in-one unit.

By combining GenH2 liquefaction, storage, and transfer units into one system, synergies occur from design optimization that results in process performance improvements throughout the hydrogen value chain. Allowing multiple processes to take place in an integral system enhances the efficiency and practicality of the hydrogen solution. The complete hydrogen system also has a compact, smaller footprint than most hydrogen systems available, so it provides additional versatility and cost savings. Components are also designed to be scalable which enables added growth flexibility.

A combined system would be the ideal approach in using the GenH2 components to maximize performance. The GenH2 LS20 Mobile Hydrogen System is a perfect example of such a complete system as it incorporates all the earlier-mentioned components into one combined unit. This results in a complete one-system solution for hydrogen processes that would normally require piecing together several different individual systems to accomplish the same result.

Download our Solution Brief to learn more about the benefits of combining units to create complete hydrogen systems!

- Precooling

- Liquefaction

- Storage/Compression

- Dispensing