Our Solutions are Scientifically Innovative

The Hydrogen Future is NOW!

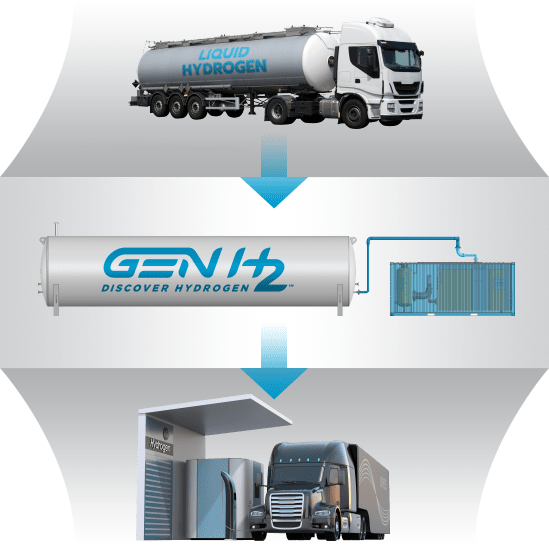

GenH2 technology can be used as an energy carrier for back-up power generation, fuel-cell supply, clean energy storage, and transportation.

Liquefaction exposes the gaseous hydrogen to extreme conditions which cause it to both cool and condense into a liquid form, making it a more efficient energy carrier. Liquid hydrogen is denser than gaseous hydrogen, so it offers more energy in a smaller space. GenH2 focuses on innovative light-scale liquid hydrogen technologies to meet the hydrogen economy infrastructure needs inspired by research and testing by former NASA scientists and engineers. GenH2 offers 3 liquefaction products including small-scale (2-20 kg/day), medium-scale (100 kg/day), and industrial-scale (1000 kg/day).

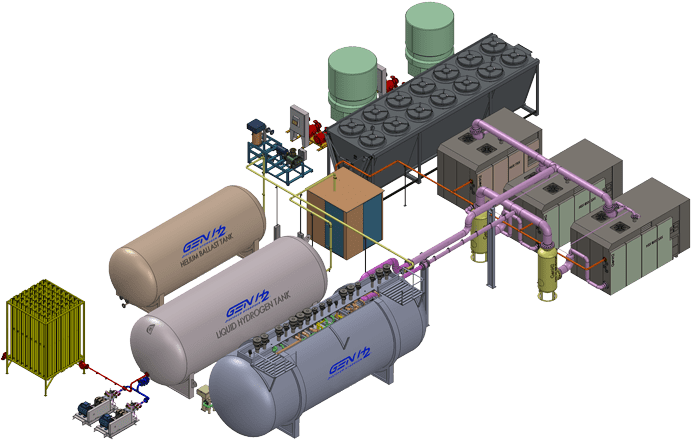

Controlled Refrigerated Storage is a key aspect in maintaining liquid hydrogen (LH2) and is essential in keeping it in its liquid phase, energy-dense, and manageable. Attempts to maintain LH2 in an ambient environment would be the equivalent of attempting to prevent water from boiling on a hot stove. To minimize hydrogen boiloff, innovations pursuing zero-loss storage solutions have resulted in the inventive Controlled Refrigerated Storage systems. Based on technology pioneered by the NASA Kennedy Space Center and the NASA Marshall Space Flight Center, controlled storage offers full control over the contained LH2. This level of control allows for greater operational efficiency, flexibility in ground operations, and overall enhanced performance. GenH2 standard controlled storage system is a 2.4MT with zero-loss transfer and zero-boiloff.

GenH2’s controlled refrigerated transfer (CRT) technology is capable of being integrated into any transfer or distribution system. Transferring and dispensing the hydrogen is accomplished using a transfer line with GenH2’s Controlled Refrigerated Transfer and Controlled Refrigerated Storage systems creating an end-to-end zero-loss hydrogen solution. This system allows for the safe transfer of liquid hydrogen while also maintaining the liquid hydrogen’s cryogenic temperature. Combining the adaptability of this system with the benefit of being zero-loss allows the liquid hydrogen transfer technology to effectively operate as a seamless filling or refilling mechanism. GenH2 is developing hydrogen transfer systems that are optimized for safety, reliability, and efficiency while maximizing performance.

While GenH2 hydrogen components can function individually, combining them to form an integral complete unit enhances the full potential of our liquid hydrogen systems. These capabilities translate to greater efficiency in liquid hydrogen solutions, which involves the combined integration of GenH2’s Liquefaction, Storage, and Transfer systems. Integrating Liquefaction, Storage and Transfer units to create a singular functioning system leads to time and space savings, as well as a smaller footprint than individual components. GenH2’s hydrogen systems are designed to work both independently and concurrently with one another, allowing for modular compatibility and growth scalability.

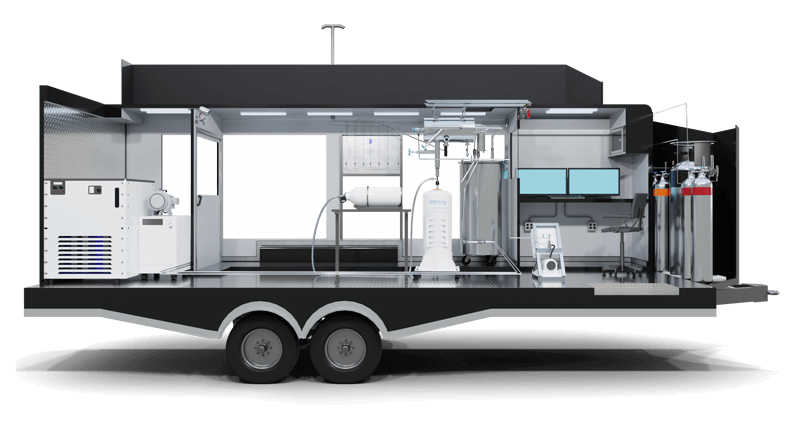

GenH2’s Mobile Liquid Hydrogen System, the LS20, is among the smallest hydrogen liquefaction and storage systems commercially available. The LS20 provides a complete system for light-scale liquefaction, storage, and transfer of hydrogen. This system operates in a small mobile footprint that can provide liquid hydrogen for a variety of uses when and where it is needed. Applications for the Mobile Liquid Hydrogen System include on-demand LH2 supply, backup power generation, localized hydrogen liquefaction, emergency response, and clean energy storage. GenH2’s LS20 offers 2-20 kg of liquid hydrogen.

Cryostats are simulation test apparatus or platforms that allow contained objects to reach and maintain extremely low-temperature levels. With liquid cryogen-cooled cryostats such as the Macroflash, this is done through a process of adding a cryogenic liquid, such as liquid helium or (In the case of the Macroflash) liquid nitrogen around a container holding the sample object. This boiloff fluid is responsible for achieving cryogenic temperatures and is maintained at a designated level. Determining how much fluid evaporates helps measure heat conductivity in the sample material. Different types of cryostats are being used for simulating real-life conditions under a range of pressures and temperatures, and to aid design and scientific efforts focused on LH2 supply systems, space exploration, medical technology, microscopy, and spectroscopy. GenH2 currently offers CS10, CS100, CS500 and CS900 Cryostats for cryogenic testing.

The Macroflash, or Cup Cryostat measures the heat conductivity of specimens. The Macroflash testing instrument offers a user-friendly, time-efficient means to analyze material heat conductivity. The instrument is cost-effective due to its compact size, ability to work without a vacuum chamber, and capacity to undergo multiple daily tests. As a result of its efficiency and effectiveness, the Macroflash is a precise measurement tool suitable for numerous commercial use cases and advanced research.

Minimizes CO2 emissions.

Public and private funded research

Over 3 decades of hydrogen experience

Please provide your information below to download this resource.