Transferring Hydrogen Across the Value Chain

By: GenH2 Staff

Read Time: 3 minutes

As the world moves to new energy sources and hydrogen demand increases, solutions to contain the molecule will become critical for clean energy transition. Being the smallest molecule, hydrogen easily escapes so it is particularly difficult to contain it and prevent boil-off. No one wants to lose precious energy sources so zero-loss systems are essential to controlling hydrogen and minimizing loss. Without using zero-loss systems such as controlled refrigerated storage or transfer lines, a great deal of hydrogen would be lost throughout the value chain. These systems prevent significant loss of hydrogen which in turn decreases operating costs. This is especially true for liquid hydrogen (LH2) which is the preferred choice for the highest purity.

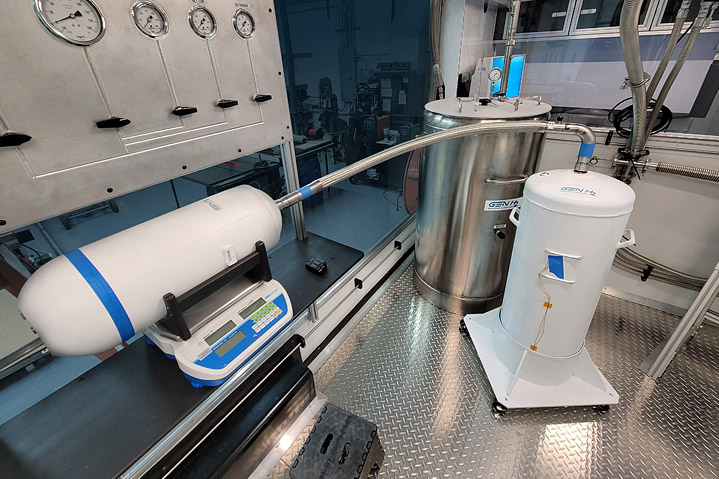

To keep liquid hydrogen energy-dense and pure, advanced refrigerated storage systems are used to enhance its longevity and eliminate boil-off. Additional challenges arise when the hydrogen is offloaded from the storage systems. The process of transferring the hydrogen from its storage source to the end use is often an overlooked step in the value chain. Significant hydrogen can be lost during the offtake process unless a zero-loss transfer line is used. A controlled refrigerated transfer system operates like controlled refrigerated storage by using insulation to prevent boil-off and preserve the liquid hydrogen.

The LH2 transfer and distribution process is a key piece to the puzzle enabling the success of hydrogen as a clean energy option. When the time comes to distribute the liquid hydrogen, a specialized vacuum-jacketed transfer system is used. As vacuums do not conduct heat, they provide the perfect insulation to retain hydrogen in its liquid form for efficient distribution.

Liquid hydrogen is controlled refrigerated and stored by keeping its temperature low with efficient insulation and ensuring rapid transfer to minimize the time spent moving it between systems. When liquid hydrogen is transferred by vacuum insulted lines, the energy (heat) coming into the complete system is minimized. Rapid LH2 transfer also allows for quicker refueling times in addition to energy preservation. These insulation methods induce a property known as zero-loss, which is an essential element for any liquid hydrogen system.

In zero-loss systems, hydrogen can remain stable in its liquid form indefinitely. Liquid hydrogen’s unmatched energy density makes it the ideal energy carrier. As a result, the systems that use and distribute the LH2 must also be able to prohibit boil-off to truly realize its benefits. Additionally, the use of zero-loss transfer systems creates energy savings while reducing costs associated with hydrogen loss.

Ideally, all future liquid hydrogen systems will be capable of achieving zero-loss to enhance energy retention and longevity. This will ultimately provide unmatched efficiency in LH2 operations, ensuring a brighter path to achieve a greener future.

GenH2’s mission is to create light-scale infrastructure solutions for the liquid hydrogen value chain, focusing on the liquefaction, storage, and transfer of hydrogen. Smaller scale options offer a clear path to accelerate widescale infrastructure rollout including the development of zero-loss liquid hydrogen transfer technologies. To learn more about light-scale hydrogen storage, distribution, and transfer, see our previous blog post on Uniting the Grid with Liquid Hydrogen!