Hydrogen A to Z Series: M For Modularity

By: GenH2 Staff

Read Time: 2 minutes

Defining the Hydrogen Economy from A to Z: M is for Modularity

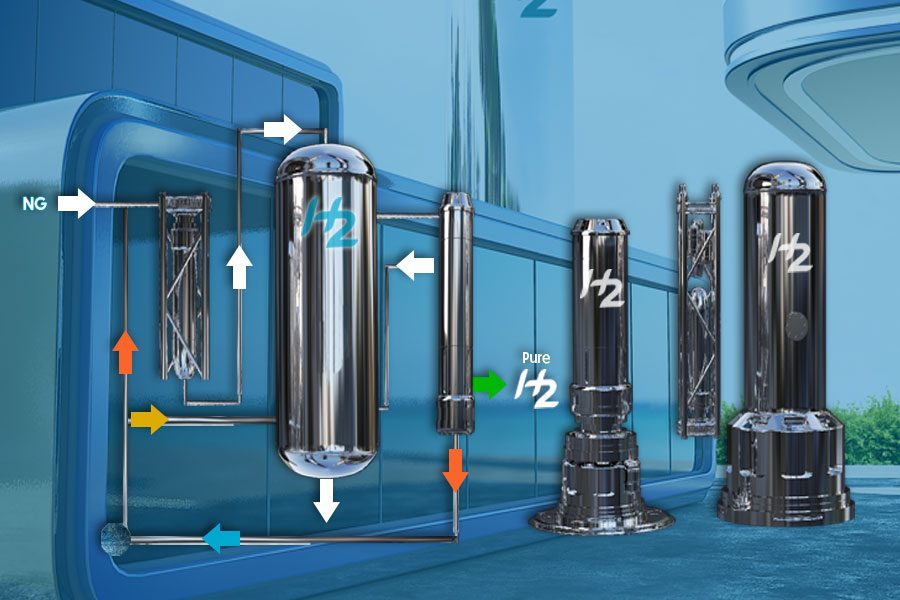

Continuing on in our defining the Hydrogen economy from A to Z series, we are focusing on the letter M for Modularity. One of the key design criteria to bolstering the hydrogen economy is modular design; modular design provides a level of flexibility that highly customized systems could never achieve. At GenH2, we believe in designing our products and systems with scaling, parallel processes and augmentation in mind.

People may have heard of modular design in electronics or the car industry, but what about the liquid hydrogen and cryogen industry? Well, some of the ways we achieve modularity is by using some readily sourced components from key suppliers. These components are then designed to “plug in” to our system in a simplified manner. For example, by designing a liquefaction chamber to accept larger cryocoolers, we’re able to effectively double LH2 with a simple swap of the component. Increasing productivity is not the only goal, we’re able to adjust footprint, decrease production cost, increase safety, decrease O&M, increase the longevity, and decrease the time to market. Modular design might come with many advantages, but the design itself is carefully thought out and can go through a rigorous and long design phase. One must look at present and future technologies and how the system would interact with products in early design phases. Essentially, it involves a lot of research and foresight. As such, the expertise is key in modular design, as well as having solid, working relationships with suppliers, vendors, contractors, and in-house production and fabrication.

It’s not without its challenges, particularly for emerging industries like the one we’re involved in. There are few key players in certain roles and the market is largely dominated by those. For example, there are only a few companies in the United States that make large helium compressors, or 20 kelvin cryocoolers, or liquefaction cold boxes. The challenge of balancing relationship and acquiring expertise is a crucial one to overcome. As the industry grows and there are more players in the hydrogen infrastructure game, the goal for making everything inhouse might even become a necessity as more mergers and acquisitions happen. Regardless, we’ll always look at modular design as the first choice for GenH2’s products and systems. Please follow us next week as we discuss another element, Nitrogen, and specifically Liquid Nitrogen and the role it plays in the Hydrogen economy.

Blog written by GenH2 team member: Julien Thomas and Co-Authored by Martha Williams, Ph.D.