GenH2 Manufactures Macroflash Test Instrument

By: GenH2 Staff

Read Time: 4 minutes

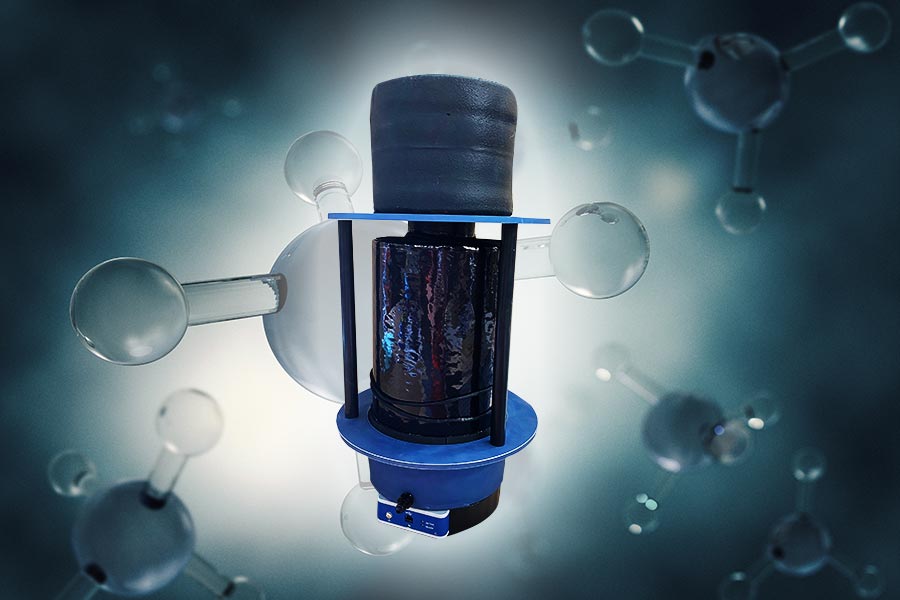

GENH2 MANUFACTURES WORLD-CLASS NASA KENNEDY SPACE CENTER LICENSED MACROFLASH TEST INSTRUMENT

South Dakota School of Mines & Technology Receives First Commercialized Version of Compact Instrument that Measures Thermal Conductivity of Materials at Below-Ambient Temperatures

GenH2 Manufactures World-Class NASA Kennedy Space Center Licensed Macroflash Test Instrument (prweb.com)

Titusville, Fla. (December 9, 2021) – GenH2, a leader in commercializing and mass-producing advanced technology solutions, announced it is the first and only company currently manufacturing and distributing a new Macroflash test instrument under a technology transfer license from NASA Kennedy Space Center (KSC). The further development and manufacturing by GenH2 will follow more than a decade of internal research use in the space program by the company’s Chief Technology Officer, James Fesmire, a world class cryogenic engineer, scientist, and leading hydrogen technologies expert. Fesmire is also the inventor of the Macroflash technology, which was carried out under the umbrella of the KSC Cryogenic Test Laboratory. Also known as a Cup Cryostat, the compact instrument measures thermal conductivity of materials or complex composites at below-ambient temperatures or subjected to a large temperature difference.

The South Dakota School of Mines & Technology (South Dakota Mines), a science and engineering university in Rapid City, South Dakota, is the first to receive the commercialized version of the Macroflash, which will be used in energy, transportation, construction and environmental sectors. It will be employed for such applications as engineered systems, research testing and quality control in manufacturing. Other potential applications include electrical power and energy storage; refrigeration and cryogens; aerospace and advanced materials construction; and ground and air transportation.

“We are delighted to have our own instrument in-house after years of advanced materials collaborative research work with James Fesmire, as well as the team at the Cryogenics Test Laboratory of NASA Kennedy Space Center,” stated Dr. David Salem, director of the Composites & Polymer Engineering Laboratory (CAPE Laboratory) at South Dakota Mines. “The new instrument will be used to advance materials research for severe and extreme conditions, including immediate application in a five-year research program we are conducting with the U.S. Army’s Cold Regions Research and Engineering Laboratory (CRREL).”

“Accurate thermal performance information, including effective thermal conductivity data, are needed under relevant end-use conditions across diverse industries,” said Fesmire. “By mass producing the Macroflash, industry and research institutions have a practical tool for basic testing of common materials or research evaluation of advanced materials and systems.”

Advances in new polymers and composites along with growing industrial needs are the impetus for the Macroflash development. Among its many benefits, the Macroflash is compact, easy to use and cost-effective compared to other commercially available thermal test instruments. The device’s small size is advantageous for test specimens (typically 75mm in diameter and 6mm in thickness), including solids, foams, or powders, that are homogeneous or layered in composition. In addition, multiple tests can be completed in one day, with no costly vacuum chamber set-up required.

The Macroflash technology uses liquid nitrogen as a direct heat energy meter and is applicable to testing at a wide range of temperatures from 373 K down to 77 K and under an ambient pressure environment. It operates with a cold side, maintained by liquid nitrogen at 77 K while a heater disk maintains a steady warm-side temperature from ambient up to 373 K. The steady boiloff of the liquid nitrogen provides a direct measure of the heat energy transferred through the thickness of the test specimen. Nitrogen or other gas is supplied to the instrument to establish a stable, moisture-free, ambient pressure environment. Different compression loading levels can also be conveniently applied to the test specimen as needed for accurate, field representative thermal performance data. The Macroflash is calibrated from approximately 10 mW/m-K to 800 mW/m-K using well-characterized materials.

The Macroflash follows the guidelines of the newly established technical standard ASTM C1774 (Annex A4). For more information, please visit https://technology.nasa.gov/patent/KSC-TOPS-22.

To learn how to procure a Macroflash from GenH2, please contact support@genh2hydrogen.com.

About GenH2

GenH2 is an industry leader in hydrogen infrastructure solutions. The Titusville, Florida-headquartered technology company team includes former NASA researchers and developers who possess decades of experience researching, engineering and producing hydrogen solutions. At GenH2, they are focused on the mass production of infrastructure solutions necessary for the transition to a clean energy economy and enabling technologies that support that mission such as the Macroflash. GenH2 technology will allow safe onsite production, storage and distribution of pure liquid hydrogen, making the product accessible for everyday use. GenH2’s innovative technologies include solutions to make high purity hydrogen on site with the goal of zero CO2 emissions; the company has plans to deliver its product to hundreds of locations across the country in the coming years.

Media Contact:

Melissa Perlman

BlueIvy Communications

561-310-9921

GenH2@blueivy.co

Copyright All Rights Reserved GenH2

Copyright All Rights Reserved GenH2

Copyright All Rights Reserved GenH2

Copyright All Rights Reserved GenH2 Copyright All Rights Reserved GenH2

Copyright All Rights Reserved GenH2